IntroductionSupercritical Fluid Foaming (SCF) represents the technological zenith of modern footwear manufacturing. More than just a new material, it is a process revolution that renders traditional chemical foaming obsolete. By integrating this physical foaming process, Aybroad has successfully reconciled the long-standing conflict between low density and high rebound, providing a near-perfect solution for elite racing shoes and premium functional insoles.

Technical Principle: A Pure Physical Transformation

Unlike traditional methods reliant on Chemical Blowing Agents, SCF technology utilizes Nitrogen (N₂) or Carbon Dioxide (CO₂) in a supercritical state—possessing the diffusivity of a gas and the solubility of a liquid—to permeate the base polymer (such as EVA, PEBA, or TPEE).

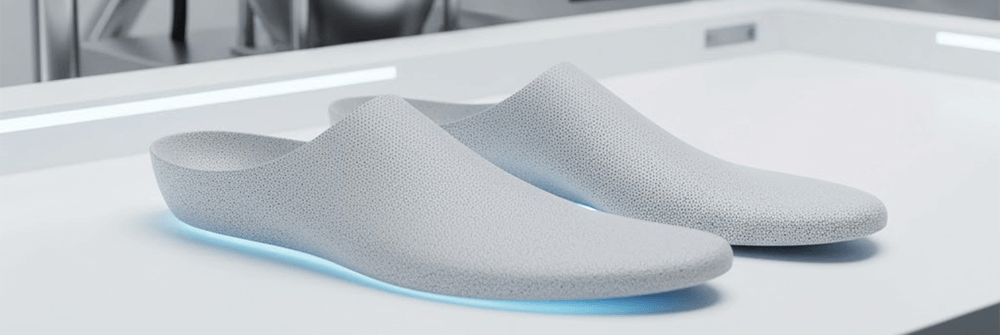

Upon the instantaneous release of pressure and temperature, the gas creates billions of uniform, microcellular (nano-to-micro scale) pores within the material. This process yields materials with densities below 0.1g/cm³, while maintaining exceptional structural integrity and toughness—achieving a true "weightless" feel.

Aybroad’s Engineering Edge: Precision Temperature & Pressure Control

The primary challenge of SCF lies in the extreme control of the autoclave’s pressure and thermal fields. Aybroad utilizes advanced high-pressure autoclave equipment and a highly experienced engineering team. We precisely calibrate gas saturation times and decompression rates to fine-tune pore size and wall thickness.

This capability allows us to customize mid-sole plates with energy return rates exceeding 75% or top-layer cushioning with an exquisitely fine tactile feel. Our products are free from chemical odors and exhibit superior batch-to-batch consistency.

Applications & Market Outlook

SCF is the dominant choice for marathon carbon-plated racing foams. For our B2B partners, Aybroad provides supercritical sheets ideal for high-end replacement insoles and the core cushioning layers of professional sports gear, empowering brands to outperform competitors in key performance metrics.