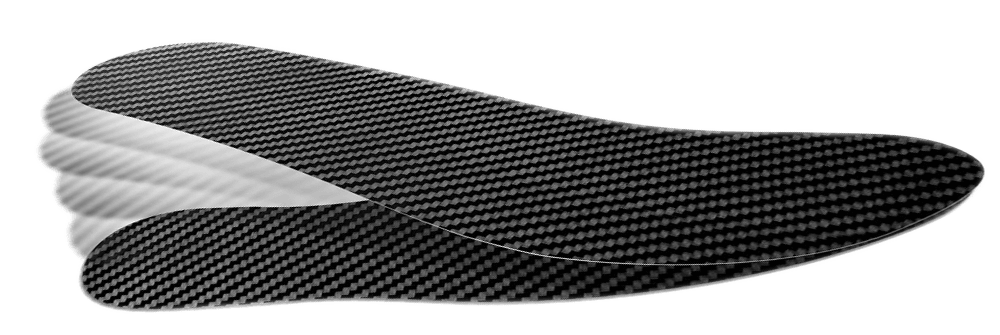

Introduction In the realm of elite competitive sports, Carbon Fiber is undoubtedly the "crown jewel" of material science. Originally reserved for aerospace engineering and Formula 1 racing, this cutting-edge material has become the essential core for structural stability and energy transmission in premium athletic insoles. Aybroad integrates precision carbon fiber layup processes into insole manufacturing, providing unparalleled support for professional athletes and high-performance enthusiasts.

Core Physical Advantages: Extreme Specific Strength

The defining characteristic of carbon fiber is its incredible strength-to-weight ratio. Its tensile strength is several times that of steel, while its density is significantly lower than aluminum alloy.

In insole applications, an ultra-thin carbon plate (as thin as 1.0mm) provides immense torsional rigidity. During toe-off, the carbon plate acts like a spring—storing and instantaneously releasing energy to provide powerful propulsion. Simultaneously, it stabilizes the midfoot, preventing lateral roll and potential injury during high-intensity movements.

Aybroad’s Precision Manufacturing: Pre-preg & Compression Molding

The performance of carbon fiber is highly dependent on the manufacturing process. Aybroad utilizes professional Pre-preg Lay-up technology:

-

Engineered Orientation: Our engineers precisely design the weave angles (e.g., Unidirectional-UD, 3K Twill) and stacking sequences based on the specific force vectors required.

-

Consolidated Forming: Through high-temperature and high-pressure compression molding, we ensure perfect resin infiltration and zero-void defects. This results in maximum structural integrity and the iconic, high-gloss 3D woven aesthetic. We are capable of producing complex 3D contoured carbon plates that anatomically match the arch of the foot.

Applications

Carbon fiber is the primary choice for propulsion plates in marathon racing shoes, anti-torsion shanks in basketball footwear, and rigid bases for high-end medical orthotics. Aybroad offers a range of options, from 100% carbon fiber to carbon-composite hybrids.