Select your language

WHO WE ARE

Established in 2003 in Dongguan—the world’s footwear capital—Aybroad is a fully integrated enterprise dedicated to the R&D, design, manufacturing, and global distribution of premium footcare products.

WHAT WE DO

We provide bespoke design and manufacturing solutions for premium footcare products, specializing in PU, GEL, TPR, and EVA insoles, as well as metatarsal pads, toe protectors, and other accessories.

HOW WE DO

We are committed to exceptional quality and 100% qualification. Driven by customer satisfaction, we earn the trust of our global partners through uncompromising standards and dedicated service excellence.

WHY CHOOSE US

As a market-driven partner, we prioritize our clients' interests by delivering diverse, high-feasibility solutions. Our mission is to maximize client value, drive competitive advantage, and help you secure a larger market share.

-

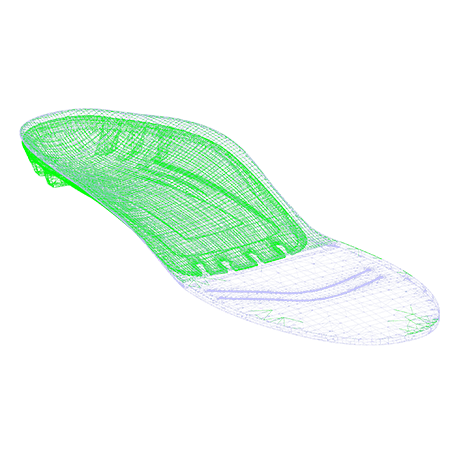

After a thorough understanding of client requirements, we initiate the design process through precision 3D scanning of samples or lasts to build digital models. We then utilize high-fidelity rendering for visual verification, followed by CNC-machined wooden molds or 3D-printed prototypes to validate structural integrity and dimensional accuracy.

Our Core Design Suite:

-

Solidworks

-

Rhino

-

Crispin

-

3DMAX

-

Illustrator

-

PhotoShop

-

AutoCAD

-

-

In the OEM/ODM business, we recognize that delivery stability and specification consistency are critical to our clients' success. By optimizing our manufacturing workflows, we ensure a precision-engineered transition from R&D prototypes to full-scale mass production:

- Design Fidelity & Execution: Whether dealing with complex dual-color EVA composite structures or specific density requirements for FOAM and POLYURETHANE, our production lines strictly adhere to your technical parameters, ensuring mass-produced units are identical to confirmed samples.

- Standardized Grinding & Finishing: Utilizing large-scale mechanical grinding paired with rigorous jig-controlled processes, we ensure every batch—from thousands to tens of thousands of pairs—maintains uniform dimensions, edge smoothness, and arch curvature, reducing your assembly costs and defect rates.

- Efficient Capacity Management: Leveraging a mature mass-production management system, we effectively minimize material waste and shorten lead times. While maintaining full quality compliance, we provide a competitive cost advantage and a steadfast commitment to on-time delivery.

-

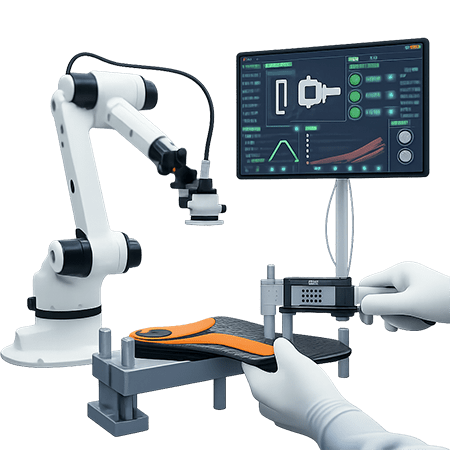

Consistency is the foundation of our mass production process. We have established a comprehensive, end-to-end quality control system—covering everything from raw material entry to final dispatch—to ensure every insole delivered meets the highest industry standards:

- Strict Raw Material Screening: We perform rigorous sampling tests on all incoming EVA, FOAM, and other raw materials for density, rebound, and eco-compliance. By eliminating quality risks at the source, we ensure all materials meet international regulatory requirements.

- Real-time In-Process Inspection: Fixed inspection points are integrated into critical stages, including dual-color injection, lamination, and grinding. Combining first-article, roaming, and final-stage inspections allows us to correct deviations in real-time and maintain stable process parameters.

- 100% Finished Goods Inspection: Every finished product undergoes 100% visual and dimensional verification. We focus on bond strength at material junctions, surface smoothness, and dimensional precision to ensure no glue overflow, no deformation, and zero defects.

- Reliability & Physical Testing: We conduct regular physical performance tests, including abrasion resistance, compression set, and color fastness. Our quality is backed by data, ensuring products maintain peak performance in diverse environments.

“Through rigorous control of every detail, we minimize your after-sales risk and safeguard your brand reputation.”

-

-

Reinforced Packaging

We utilize export-standard 5-ply reinforced corrugated cartons with anti-crush stacking designs specifically for EVA/FOAM materials. This ensures cargo remains intact, dry, and deformation-free during long-distance maritime transit. -

Full Customization

From eco-friendly tapes to premium custom color boxes, we provide comprehensive packaging services. We support silk-screen logo printing and personalized labeling to help your brand achieve a professional presentation in the retail market. -

Standardization & Compliance

Our standardized shipping marks and barcode management ensure easy palletization and efficient warehouse handling. These streamlined logistics protocols significantly reduce your labor costs during inventory and distribution. -

Deformation Prevention

We design specialized internal linings or support structures tailored to the ergonomic curvature of our insoles. This prevents functional damage from bulk compression, ensuring every pair arrives in optimal condition. -

Sustainability & Optimization

By optimizing packaging dimensions, we reduce wasted volume to save on your freight costs. We utilize recyclable, eco-friendly materials that align with global plastic-reduction trends and enhance your brand's green image.

-

Reinforced Packaging

-

Proactive Production Control & Scheduling: We have established a sophisticated production dispatch system that translates every order into a meticulously managed timeline. Through scientific forecasting of raw material reserves, production line loads, and workflow synchronization, we achieve full-process visibility from order placement to final output. This proactive approach not only significantly shortens lead times for OEM/ODM orders but also ensures a disciplined production rhythm even when facing urgent requests or high-volume surges, providing steadfast capacity support for our clients' sales strategies.

Lifecycle-Integrated Quality Assurance: Quality is not merely inspected; it is engineered into the product. We embed quality consciousness into every phase of manufacturing: from the physicochemical analysis of incoming materials to first-article inspections, roaming checks, and SPC (Statistical Process Control) during production, culminating in 100% simulated packaging inspections. Through this rigorous closed-loop quality management, we guarantee the functional stability of EVA/FOAM materials and the precision of our grinding processes, eliminating deviations on the line and building a robust quality barrier for your brand.

Scientific Management: Where Digital Meets Human Excellence: We implement a standardized management model that breaks down complex production workflows into quantifiable Standard Operating Procedures (SOPs). By integrating advanced management tools with regular skill assessments, we maintain a baseline of high-standard, high-efficiency performance. Our scientific approach extends beyond equipment maintenance and process refinement to encompass rapid response to client feedback and continuous optimization. Through data-driven decision-making, we constantly improve resource utilization and product consistency, creating premium value for our clients through competitive cost structures.

-

To better serve our diverse global partners of all sizes, we offer highly flexible trade and settlement solutions designed to ensure a seamless cooperation process:

- Diverse Financial Settlement Options: We support flexible tax and accounting treatments tailored to your reporting and cost-accounting needs. Depending on your requirements, we can provide tax-inclusive pricing or net-price settlement. We fully respect and comply with the financial regulatory requirements of different countries and regions, ensuring every transaction is clear, transparent, and compliant.

- Comprehensive Trade Terms (Incoterms): Regardless of your logistics resources, we provide delivery solutions that match your capabilities. We are experts in handling standard terms from EXW (Ex Works) and FOB (Free on Board) to CIF (Cost, Insurance, and Freight). For clients seeking a hassle-free experience, we also offer DDU/DDP (Delivered Duty Unpaid/Paid) services, achieving a true one-stop, door-to-door experience from our production line to your warehouse.

- Customized Cooperation Models: Our commercial flexibility extends beyond logistics and taxation. We offer tiered Minimum Order Quantities (MOQ) and credit-based payment terms for long-term strategic partners. We are dedicated to reducing your procurement risks and cash flow pressure through adaptable business terms.

“We don't set barriers; we build the most efficient trade pathways for your success.”